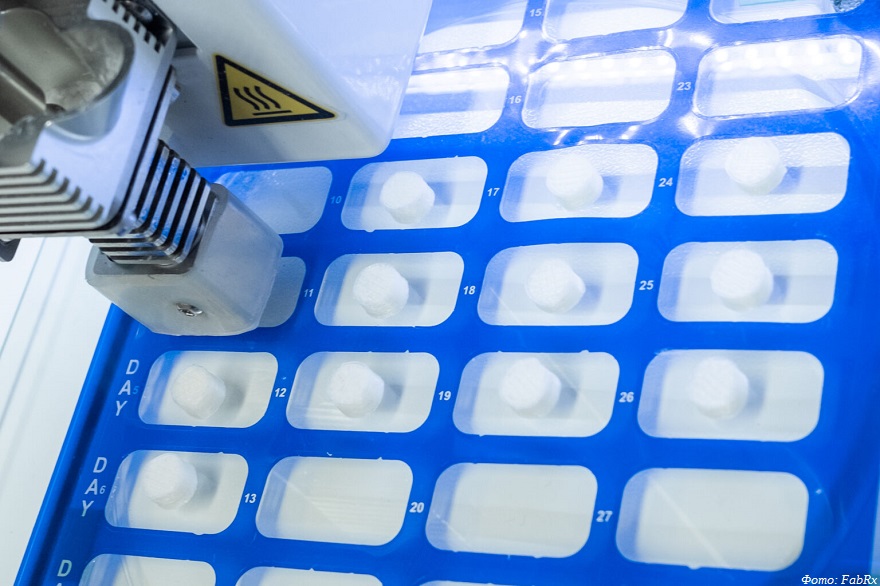

Think of a future where every pill you take is tailor-made just for you. Scientists at the University of Nottingham are leading the way with an amazing new technology. They’re using 3D printing to create tablets containing multiple drugs and programmed to release them at specific times. It’s like having your own custom-made medicine. This development, led by Dr. Yinfeng He from the University’s Centre for Additive Manufacturing and Professor Felicity Rose from the School of Pharmacy, has the potential to revolutionize how we treat diseases.

Printing on demand: How it works

The research details a novel 3D printing technique called Multi-Material InkJet 3D Printing (MM-IJ3DP). With this method, scientists can fabricate customized tablets with intricate internal structures. These structures are important because they help give you the right medicine at the right time.

The secret lies in a specially formulated ink that contains light-sensitive molecules. During the printing process, these molecules solidify upon exposure to ultraviolet light, forming a water-soluble framework within the tablet.

By carefully designing these internal structures, researchers can control the rate at which the drugs are released.

A single pill for complex regimens

This targeted release system opens doors for a future of simplified medication schedules. MM-IJ3DP enables the incorporation of multiple drugs into a single tablet. This eliminates the hassle of managing complex regimens that require taking several pills at different times.

“This is an exciting step forwards in the development of personalized medication,” explains He.

“This breakthrough not only highlights the potential of 3D printing in revolutionizing drug delivery but also opens up new avenues for the development of next-generation personalized medicines,” he added.

Overcoming challenges for widespread adoption

While the potential of MM-IJ3DP is undeniable, there are still hurdles to overcome. The current technology requires the development of more ink formulations that can accommodate a wider range of medications. Researchers are actively addressing this challenge to pave the way for broader application of the technique.

“The ongoing research aims to refine these aspects, enhancing the feasibility of MM-IJ3DP for widespread application,” says Professor Ricky Wildman, another project collaborator.

Precise dosing for optimal treatment

This technology holds particular promise for conditions where timing and dosage accuracy are critical. MM-IJ3DP provides a solution for medications that require controlled release at specific intervals throughout the day.

The ability to print large batches (demonstrated by creating 56 pills in a single run) further strengthens the case for MM-IJ3DP as a viable method for large-scale production of personalized medicines.

A brighter future for medication adherence

Rose emphasizes the impact this technology can have on medication adherence, a significant issue in healthcare. “Up to 50% of people in the UK alone don’t take their medicines correctly,” she reveals.

“A single pill approach would simplify taking multiple medications at different times and this research is an exciting step towards that,” she added.

This new 3D-printed pill method could change everything. It would make medicine schedules fit you better and treat chronic diseases much better. It’s like a peek into a future where medicine is all about you.